The 2023 Texas Criminal and Traffic Law Manual is a comprehensive resource for legal professionals, detailing updated statutes, procedures, and best practices in criminal and traffic law enforcement.

Overview of the Manual’s Purpose and Scope

The Texas Criminal and Traffic Law Manual 2023 serves as a comprehensive resource for legal professionals, law enforcement, and policymakers. Its primary purpose is to provide a detailed and updated understanding of Texas statutes, including the Penal Code, Code of Criminal Procedure, and Transportation Code. The manual covers a wide scope of topics, from criminal offenses and traffic violations to search and seizure laws, ensuring a thorough reference for practitioners. It also includes practical legal frameworks, case applications, and recent legislative changes, making it an essential tool for attorneys, judges, and law enforcement officers. The manual emphasizes clarity and accessibility, bridging legal theory with real-world implementation.

Key Updates and Revisions for 2023

The 2023 edition of the Texas Criminal and Traffic Law Manual incorporates significant updates and revisions to reflect recent legislative changes and judicial rulings. Key updates include modifications to the Texas Penal Code, particularly in hate crime classifications and domestic terrorism definitions. Additionally, there are revisions to the Transportation Code addressing traffic enforcement and vehicle-related offenses. The manual also highlights new search and seizure protocols under the Fourth Amendment, ensuring law enforcement aligns with current legal standards. Furthermore, it includes expanded resources on crime prevention strategies and updated training guidelines for law enforcement officers. These revisions ensure the manual remains a reliable and up-to-date reference for legal professionals and practitioners in Texas.

Criminal Law in Texas

Texas criminal law addresses a wide range of offenses, from misdemeanors to felonies, governed by the Texas Penal Code and related statutes, ensuring justice and public safety.

Key Statutes in the Texas Penal Code

The Texas Penal Code establishes the framework for criminal offenses in the state, covering a wide array of crimes from misdemeanors to felonies. Key statutes include those related to property crimes, such as theft and burglary, as well as offenses against persons, like assault and homicide. The Penal Code also addresses organized crime, weapons offenses, and hate crimes, which have seen recent updates to align with federal definitions. Notably, Section 37.10 pertains to providing false information, a critical aspect of criminal investigations. These statutes are organized into chapters, making it easier for legal professionals to navigate and apply the law effectively in criminal proceedings.

Classifications of Criminal Offenses

Criminal offenses in Texas are classified into misdemeanors and felonies, with each category carrying distinct penalties. Misdemeanors are further divided into Classes A, B, and C, with Class A being the most severe, potentially resulting in up to one year in jail. Felonies are categorized into degrees, ranging from State Jail Felonies to First-Degree Felonies, with penalties increasing in severity. Classifications are based on the severity of the offense, with factors such as property damage, bodily harm, and intent influencing the categorization. Understanding these classifications is crucial for legal professionals to determine appropriate charges, sentencing, and jurisdiction. This framework ensures consistency in the application of criminal law across the state.

Search and Seizure Laws Under the Fourth Amendment

The Fourth Amendment protects individuals from unreasonable searches and seizures, requiring probable cause and a warrant in most cases. In Texas, law enforcement must adhere to these constitutional standards, ensuring searches are lawful and respect individual rights. The Texas Criminal and Traffic Law Manual 2023 details how state laws align with federal Fourth Amendment protections, including the exclusionary rule, which bars evidence obtained unlawfully. Officers must have reasonable suspicion for traffic stops or probable cause for arrests. The manual emphasizes proper procedures to maintain legal compliance and safeguard citizens’ rights during searches and seizures.

Traffic Law in Texas

Texas traffic law is governed by the Transportation Code, covering violations, penalties, and enforcement procedures. It emphasizes road safety and compliance with state regulations.

Transportation Code Provisions

The Texas Transportation Code outlines specific rules for road usage, vehicle operation, and traffic enforcement. It covers speeding, reckless driving, and DUI offenses, with detailed penalties for violations. The code ensures uniform traffic laws across the state, promoting public safety and order. Law enforcement relies on these provisions to conduct stops and issue citations. Recent updates reflect legislative changes aimed at addressing emerging issues like distracted driving and vehicle safety technologies. By adhering to the Transportation Code, Texas maintains a structured approach to managing its roadways and protecting motorists. Compliance with these provisions is crucial for drivers to avoid legal consequences.

Common Traffic Violations and Penalties

Texas traffic laws address a range of common violations, including speeding, reckless driving, and driving under the influence. Speeding penalties vary based on the exceedance over the limit, with fines escalating for repeat offenses. Reckless driving, defined as willful disregard for safety, carries higher penalties, including license suspension. Driving under the influence (DUI) is strictly enforced, with severe consequences such as mandatory jail time, hefty fines, and license revocation. Additionally, failure to obey traffic signals and seatbelt violations result in citations and potential points on a driver’s record. These penalties aim to deter unsafe driving practices and ensure road safety across Texas.

Law Enforcement Practices in Traffic Stops

Texas law enforcement practices in traffic stops are governed by legal standards ensuring safety and accountability. Officers must have reasonable suspicion of a traffic violation or criminal activity to initiate a stop. During stops, officers typically request identification, insurance, and vehicle registration. Drivers are expected to comply with instructions, and refusal can escalate the situation. The Fourth Amendment protects against unreasonable searches, requiring probable cause for vehicle searches. Officers document interactions, often using body cameras for transparency. Traffic stops aim to enforce traffic laws and prevent criminal activity, with officers trained to handle situations professionally and courteously while maintaining public safety and legal compliance.

Law Enforcement Resources and Training

The Texas Criminal and Traffic Law Manual 2023 provides law enforcement with essential resources and updated training programs to ensure effective and lawful policing practices.

The Role of the Texas Criminal and Traffic Law Manual

The Texas Criminal and Traffic Law Manual 2023 serves as a critical resource for law enforcement, attorneys, and legal professionals, providing a comprehensive collection of Texas statutes, including the Penal Code, Code of Criminal Procedure, and Transportation Code. It outlines essential legal frameworks for criminal and traffic enforcement, ensuring adherence to constitutional rights and procedural standards. The manual is updated annually to reflect legislative changes and judicial rulings, making it an indispensable tool for staying informed on current laws. Its role extends to training programs, helping law enforcement officers understand and apply legal principles effectively in their daily operations. It bridges legal theory and practical application, ensuring justice is served consistently across Texas.

Training Programs for Law Enforcement Officers

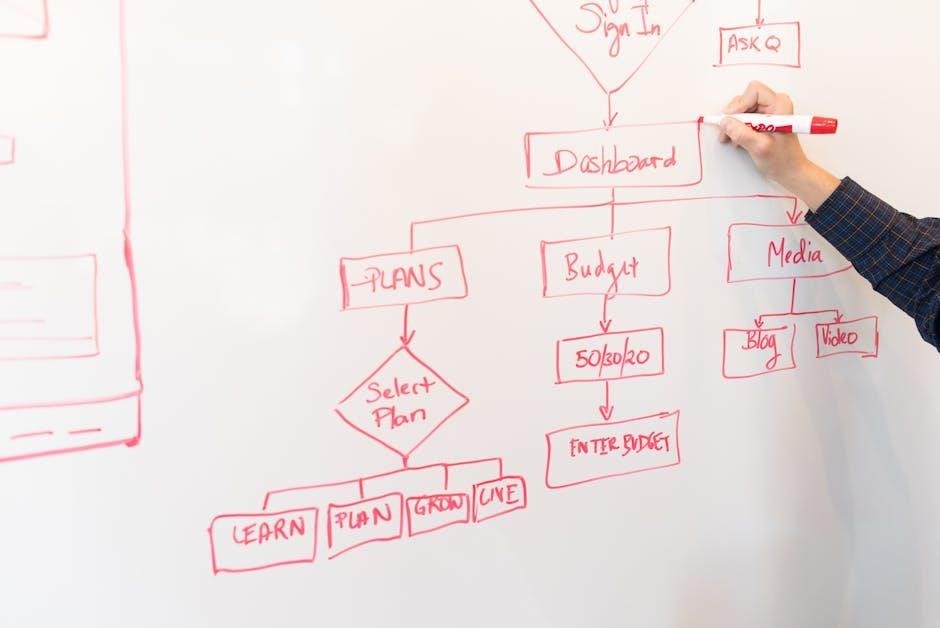

Training programs for law enforcement officers in Texas are designed to ensure they are well-versed in the latest legal updates and procedural standards. These programs utilize resources like the Texas Criminal and Traffic Law Manual 2023 to educate officers on statutes, including the Penal Code and Transportation Code. Training covers critical areas such as search and seizure laws, arrest procedures, and hate crime classifications. Officers also receive guidance on handling traffic stops and understanding reasonable suspicion standards. These programs aim to enhance professionalism, reduce liability, and ensure constitutional compliance. By staying informed, officers can apply the law effectively, maintaining public trust and upholding justice in their communities. Regular updates keep training relevant and aligned with legislative changes.

Recent Reforms and Updates in Criminal and Traffic Law

Recent reforms in Texas criminal and traffic law address hate crime classifications, domestic terrorism definitions, and updated penalties for certain offenses, ensuring laws remain aligned with justice and safety priorities.

Legislative Changes Affecting Criminal Justice

Legislative changes in Texas for 2023 focus on enhancing penalties for hate crimes and clarifying domestic terrorism laws. These updates aim to address evolving threats and ensure justice systems adapt to contemporary challenges. New statutes emphasize stricter enforcement of traffic violations to improve road safety. Additionally, reforms in criminal procedure streamline processes for law enforcement, ensuring procedures are both efficient and constitutional. These changes reflect a commitment to public safety and the fair administration of justice, providing clear guidelines for legal professionals and law enforcement officers statewide. The updates are detailed in the 2023 Texas Criminal and Traffic Law Manual, serving as a critical resource for practitioners.

Impact of Hate Crime Laws and Domestic Terrorism

Hate crime laws in Texas have been strengthened to address crimes motivated by bias, ensuring enhanced penalties for offenses targeting individuals based on race, religion, or other protected characteristics. Domestic terrorism, while not explicitly defined as a federal crime, is now prioritized in law enforcement strategies. The 2023 manual highlights how these laws intersect with criminal justice, providing clarity for prosecutors and officers. Recent reforms emphasize the need for vigilance in identifying and prosecuting hate-motivated acts, aligning with federal guidelines. Law enforcement agencies are now more equipped to handle such cases, ensuring public safety and upholding justice for victims of hate crimes and domestic terrorism threats.

The 2023 manual equips Texas legal professionals with essential updates, ensuring they stay informed and effective in their roles. It remains a vital resource for justice.

Importance of Staying Informed About Legal Changes

Staying informed about legal changes is crucial for ensuring justice and accountability in Texas. The 2023 manual highlights recent reforms, including updates to hate crime laws and domestic terrorism definitions, which impact criminal proceedings. Legal professionals must remain vigilant to avoid oversight and ensure compliance with evolving statutes. The manual serves as a vital tool, providing clarity on new laws and their implications. By referencing this guide, law enforcement and attorneys can navigate complex legal landscapes effectively, preventing errors and upholding fairness in the justice system. Regular updates ensure practitioners remain informed, adapting to changes that shape criminal and traffic law enforcement in Texas.

Future Trends in Texas Criminal and Traffic Law

Future trends in Texas criminal and traffic law emphasize technological advancements and proactive measures to combat emerging crimes. Enhanced use of data analytics and AI in law enforcement is expected to improve crime prevention and resolution. Vehicle crime prevention initiatives, such as advanced license plate recognition systems, will likely expand to curb theft and illegal activities. Additionally, there may be a stronger focus on addressing domestic terrorism and hate crimes through stricter enforcement and updated legal frameworks. Mental health integration into criminal justice systems could also become a priority to address underlying causes of criminal behavior. Staying informed about these trends is essential for legal professionals to adapt and enforce laws effectively.