This manual provides essential guidance for operating and maintaining your Mitsubishi MSZ-GL12NA unit․ It covers installation, operation, and troubleshooting, ensuring efficient performance․ Detailed instructions and technical specifications are included, along with environmental considerations for optimal use․ PDF versions are available for easy reference, and service details are provided for professional support․ Always follow safety guidelines for best results․

Overview of the Manual

The manual is structured to guide users through the Mitsubishi MSZ-GL12NA’s features, installation, and operation․ It includes detailed instructions for remote control, safety precautions, and maintenance․ The manual also provides technical specifications and energy efficiency details․ Always follow guidelines for optimal performance and safety․ The comprehensive guide is available in PDF format for easy reference․

Structure and Content of the Manual

The user manual for the Mitsubishi MSZ-GL12NA is organized to provide clear guidance on the unit’s operation and maintenance․ It includes sections on pre-installation requirements, tool preparation, and installation steps․ Additional content covers remote control usage and energy-saving features․ Technical specifications, safety guidelines, and maintenance tips ensure optimal performance․ The manual also provides troubleshooting advice and error code interpretations․ Downloadable PDF versions make accessing information convenient․

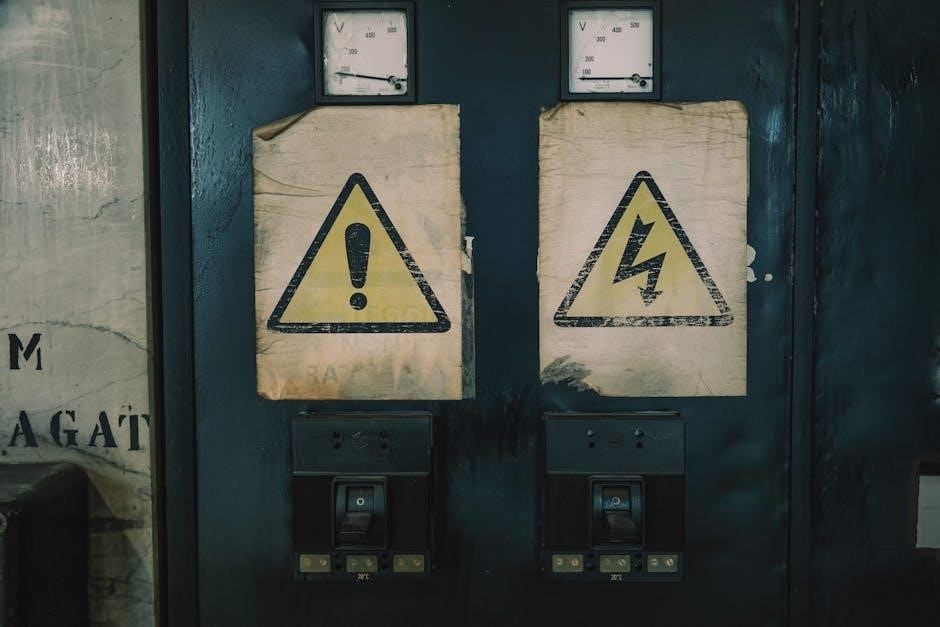

Safety Precautions and Guidelines

When handling or installing the Mitsubishi MSZ-GL12NA, ensure all electrical components are powered off to prevent accidents․ Follow weight limits and use proper lifting techniques to avoid damage or injury․ Place the unit heat sources and flammable materials․

Handle refrigerants with caution, adhering to international standards and guidelines․ Regularly clean or replace filters, following specified procedures to prevent dust inhalation or contamination․ Post-installation, conduct thorough system checks for leaks or issues before operation․

Be mindful of operational noise levels and temperature extremes․ Always read the entire manual before installation or use, and keep it accessible for future reference․

Handling and Storage of the Unit

When handling the Mitsubishi MSZ-GL12NA, use proper lifting techniques and equipment to prevent injury or damage․ Keep the unit upright during transport to safeguard internal components․

Store the unit in a dry, shaded area, free from temperature extremes and corrosive substances․ Secure it to prevent tipping or movement․ Avoid stacking heavy items on top․

Inspect the unit regularly during storage to prevent dust or moisture damage․ Cover it with a protective cover if possible․ For more guidance, consult the manual or contact Mitsubishi Electric․

Features and Specifications of the Mitsubishi MSZ-GL12NA

The Mitsubishi MSZ-GL12NA is equipped with advanced cooling and heating capabilities, utilizing R410A refrigerant for efficiency․ It features a user-friendly remote controller and an integrated airflow management system․ Designed for energy efficiency, it meets high performance standards, ensuring optimal comfort and operation․

Technical Specifications

The Mitsubishi MSZ-GL12NA excels with advanced technical specs, utilizing eco-friendly R410A refrigerant for superior efficiency․ Designed for 200V power supply, it ensures optimal performance․ Its powerful compressor delivers robust cooling and heating, supported by an advanced microprocessor control system․ Enhanced energy efficiency ratings ensure sustainable operation․ Detailed specs, including voltage and compressor performance, guarantee reliable and efficient residential use․

Cooling and Heating Capacities

The Mitsubishi MSZ-GL12NA offers exceptional cooling and heating performance, designed for optimal thermal comfort․ It features advanced cooling and heating capacities, ensuring efficient temperature regulation in various conditions․ With superior energy efficiency, the unit provides reliable performance, even in extreme climates․ Detailed specifications on cooling and heating outputs are provided in the manual, along with guidance on achieving maximum energy savings․ Regular maintenance ensures peak performance and long-term reliability․

Energy Efficiency Ratings

The Mitsubishi MSZ-GL12NA is designed with advanced energy efficiency, ensuring optimal performance and reduced energy consumption․ It meets strict energy efficiency standards, making it a reliable choice for eco-conscious users․ Its innovative design and smart features contribute to significant energy savings․ The unit’s energy efficiency ratings guarantee superior thermal performance while minimizing environmental impact․ Regular maintenance ensures continued efficiency and extends the unit’s lifespan․

Remote Control Features

The remote control for the Mitsubishi MSZ-GL12NA is designed to enhance user convenience and operational efficiency․ It allows you to control basic functions such as turning the unit on/off and adjusting temperature settings․ Advanced features include preset modes for heating and cooling, as well as adjustments for airflow management․ The remote’s intuitive design ensures ease of use, making it simple to navigate through various settings․ It also supports connectivity options, enabling seamless integration with other systems for added functionality․ Overall, the remote control is a key component in achieving optimal comfort and energy efficiency․

Airflow Management System

The Mitsubishi MSZ-GL12NA’s Airflow Management System is designed to optimize heating and cooling efficiency by controlling air circulation․ It features automatic adjustments to airflow direction, ensuring even distribution of temperature throughout the space․ The system’s advanced sensors allow for monitoring and adapting to environmental conditions, enhancing comfort and reducing energy consumption․ Precision control of airflow modes, such as swing or fixed settings, further customize performance to meet specific needs, making it a key component in achieving balanced indoor comfort․

Connectivity and Compatibility

The Mitsubishi MSZ-GL12NA supports seamless integration with modern smart home systems, enabling remote control via Wi-Fi or smartphone apps․ It is compatible with a wide range of connectivity options, ensuring compatibility with other Mitsubishi systems․ Advanced communication protocols allow for real-time monitoring and updates, enhancing user experience․ The unit’s connectivity features facilitate efficient setup and operation, ensuring seamless performance within any smart ecosystem․ This compatibility makes it a versatile choice for users prioritizing advanced technology and centralized home automation․

Installation Guide for Mitsubishi MSZ-GL12NA

This guide provides step-by-step instructions for installing the Mitsubishi MSZ-GL12NA unit․ It covers outdoor and indoor unit placement, refrigeration line connection, and power supply setup․ Follow proper safety protocols and electrical requirements for a secure installation․ Always consult the manual for precise details to ensure optimal performance and compliance with standards․

Pre-Installation Requirements

Before installing the Mitsubishi MSZ-GL12NA, ensure the space meets the unit’s requirements․ Verify adequate ventilation and proper electrical connections․ Check for sufficient space clearance around the unit to avoid obstructions․ Confirm the room’s load capacity and ensure the location is safe for operation․ Review the user manual’s specified conditions to guarantee optimal performance and compliance․

Tools and Accessories Needed

To install the Mitsubishi MSZ-GL12NA, gather essential tools and accessories․ A torque wrench, refrigerant charging equipment, and a manometer are required․ Safety glasses, gloves, and a multimeter are also necessary․ Hexagonal wrenches and expansion joints are provided for secure connections․ A drill and bit set may be needed for wall and ductwork․ Ensure all tools meet safety standards and refer to the manual for specific instructions before proceeding․

Additional accessories include connection bolts, pipe clamps, and a raceway for wiring․ Proper protective gear and precautionary measures are vital for safe installation․ Adhere to the manual’s guidelines for optimal performance and compliance with safety protocols․

Outdoor Unit Installation Process

For the Mitsubishi MSZ-GL12NA, begin by selecting a suitable location with proper airflow and clearance․ Ensure the area is protected from direct sunlight and away from obstacles․ Mount the outdoor unit on a sturdy base, securing it with bolts․ Connect the power supply and refrigerant lines, ensuring airtight seals․ Insulate pipes as needed and follow local codes․ Test the system for leaks and proper operation before finalizing the installation․ Always refer to the manual for detailed instructions and safety guidelines․

Indoor Unit Installation Process

For the Mitsubishi MSZ-GL12NA, position the indoor unit in a well-ventilated area, ensuring proper clearance from walls and obstacles․ Install the unit on a steady surface, securing it with anchors to prevent movement․ Connect the refrigerant line to the outdoor unit, ensuring tight seals to avoid leaks․ Follow local electrical codes when wiring․ Attach the front panel and test for proper operation․ Always consult the manual for specific instructions and safety measures to ensure optimal performance and longevity․

Connecting the Outdoor and Indoor Units

To connect the outdoor and indoor units of the Mitsubishi MSZ-GL12NA, ensure the refrigerant lines are properly matched and connected․ Secure the lines with clamps and insulate them to prevent heat loss․ Connect the electrical wiring according to the manual’s specifications․ Ensure all connections are tight and free of leaks․ Replicate the piping if necessary, and perform a thorough leak test․ Follow all safety guidelines and local codes for a safe and efficient installation process․

Refrigerant Charging and Leak Testing

To charge Refrigerant R410A, use a calibrated manifold gauge set following the manufacturer’s specifications․ Connect the low-pressure hose to the unit’s suction line and the high-pressure hose to the discharge line․ Slowly introduce the refrigerant while monitoring system pressure and temperature․ Perform leak testing using a soap solution or electronic leak detector․ Ensure no leaks are present before startup․ Always adhere to safety guidelines and local regulations for proper handling and disposal of refrigerants․

Post-Installation Checks and Tests

After installing the Mitsubishi MSZ-GL12NA, perform the following checks:

- Verify all electrical connections are secure and meet specifications․

- Ensure outdoor and indoor units are properly aligned and connected․

- Test remote control functions, including temperature adjustment and fan settings;

- Check for proper airflow from the indoor unit․

- Confirm error codes are clear and the system operates without issues․

Adhere to safety guidelines and perform these tests to ensure optimal performance․

Operating Instructions for Mitsubishi MSZ-GL12NA

Use the remote controller to adjust temperature, fan speed, and airflow․ Set heating or cooling modes as needed․ Check filter status and follow energy-saving tips for optimal performance․ Address any issues promptly to ensure reliable operation of your unit․

Here’s the text for the subheading ‘

Getting Started with the Remote Controller

‘:

Familiarize yourself with the remote controller’s layout and functions․ Use the power button to turn the unit on or off․ Adjust the temperature using the up/down arrow keys․ Select heating or cooling modes via the mode buttons․ Explore airflow options to optimize comfort․ Check the for real-time updates and settings․ Use the filter reminder to schedule maintenance․

Basic Operation Modes and Functions

Explore the Mitsubishi MSZ-GL12NA’s essential modes: heating, cooling, auto, and fan-only modes․ Use the remote to adjust temperature settings and cycle through operation modes smoothly․ The unit’s digital display provides real-time updates, ensuring precise control․ Customize fan speed and airflow direction for optimal comfort․ The microprocessor control ensures efficient performance, adapting to your environmental needs․

Fan Speed and Airflow Adjustment

This section explains how to adjust the fan speed and airflow settings on your Mitsubishi MSZ-GL12NA unit․ Use the remote controller to access fan speed options, typically ranging from low to high․ Adjusting the fan speed allows you to control airflow intensity, ensuring optimal comfort․ The microprocessor control enhances efficiency by automatically regulating fan speed based on temperature settings․ For best results, clean or replace filters regularly to maintain airflow quality and system performance․ Follow these steps for smooth and efficient operation․

Temperature Control and Settings

Adjust the temperature settings on your Mitsubishi MSZ-GL12NA using the remote controller’s dedicated buttons․ Set your desired temperature within the unit’s operating range, typically between 18°C and 30°C (64°F and 86°F)․ The system features precise temperature control and automatic adjustments to maintain comfort․ Use the preset modes to optimize heating or cooling for different times of the day․ For energy efficiency, set the temperature slightly higher in summer and lower in winter․ Regular maintenance ensures consistent performance․ Follow these steps:

- Access temperature settings via the remote menu․

- Adjust using the “+” or “-” buttons․

- Confirm changes and exit the menu․

Heating and Cooling Modes

Your Mitsubishi MSZ-GL12NA offers versatile heating and cooling modes for optimal comfort․ Access these modes through the remote controller’s intuitive interface; Select the desired operation, Whether heating or cooling, using the dedicated buttons or menus․ The system’s advanced microprocessor control ensures smooth transitions between modes․ During heating, enjoy warm, evenly distributed air, while cooling provides refreshing comfort․ Energy-saving features and noise reduction technology enhance efficiency and comfort․ Use preset modes to adapt to seasonal needs․ Follow these instructions:

- Select heating or cooling mode via the remote menu․

- Confirm settings and initiate operation․

- Monitor performance for optimal use․

Humidity Control and Dehumidification

Your Mitsubishi MSZ-GL12NA features advanced humidity control to maintain comfortable indoor air quality․ Adjust settings via the remote controller to regulate humidity levels․ Activate dehumidification mode to reduce moisture, ideal for humid environments․ Advanced airflow management enhances efficiency․ Multiple modes ensure precise comfort year-round․ Energy-efficient operation lowers energy costs while maintaining peak performance․ Regular maintenance ensures sustained efficiency and comfort․

Energy-Saving Features

Your Mitsubishi MSZ-GL12NA is designed with advanced energy-saving features to reduce consumption․ It utilizes high-efficiency R410A refrigerant for optimal performance․ Smart energy-saving modes automatically adjust settings for reduced power use․ The unit’s intelligent operation ensures efficient heating and cooling while minimizing energy waste․ Built-in hot-start technology and programmable settings help maintain comfort with lower energy costs․ Regular maintenance enhances energy efficiency for sustainable operation․

Maintenance and Care for Mitsubishi MSZ-GL12NA

Maintenance and care are crucial for prolonging the life of your Mitsubishi MSZ-GL12NA system․ Regularly clean or replace air filters to maintain efficiency․ Inspect the thermal unit for any signs of wear or damage․ Ensure proper airflow by clearing obstacles near vents․ For optimal performance, follow the manufacturer’s maintenance schedule and recommendations․

Routine Maintenance Tasks

Regular maintenance ensures optimal performance of your Mitsubishi MSZ-GL12NA system․ Begin by cleaning or replacing air filters every month to maintain airflow efficiency․ Inspect the indoor and outdoor units for dust, debris, or damage․ Ensure proper airflow by clearing nearby obstacles․ Check fan blades for wear and tighten any loose connections․ Drain pans should be cleaned to prevent mold growth․ Inspect refrigerant lines for leaks and ensure all electrical connections are secure․ Schedule professional servicing annually to address any underlying issues․

Cleaning and Replacing Filters

To maintain optimal performance, regularly inspect and clean or replace the air filters in your Mitsubishi MSZ-GL12NA․ Locate the filters inside the indoor unit cover, typically accessible for easy maintenance․ Use a vacuum or soft brush to remove accumulated dust․ If the filters are heavily soiled or damaged, replace them with genuine Mitsubishi filters․ Always refer to the user manual for specific instructions on filter replacement․ Proper filter maintenance ensures efficient airflow and prevents dust buildup, enhancing system performance and longevity․

Outdoor Unit Maintenance

Regular maintenance of the outdoor unit ensures optimal performance and longevity of your Mitsubishi MSZ-GL12NA system․ Keep the exterior clean to prevent dust and debris buildup, which can hinder efficiency․ Check for any obstructions around the unit that might impede airflow․ Inspect electrical connections to ensure they are secure and free from damage․ Replace or clean filters as needed, following the guidelines provided in the user manual․ Conduct these checks periodically to maintain peak performance and energy efficiency․

Common Error Codes and Troubleshooting

Your Mitsubishi MSZ-GL12NA system may display error codes to indicate issues․ Common codes include E1 for communication faults, E2 for sensor errors, and E3 for compressor lockouts․ Refer to the manual for a full list and their meanings․ To troubleshoot, check for obstructions, ensure proper power supply, and inspect connections․ If unresolved, consult the manual’s diagnostics section or contact Mitsubishi support for further guidance․

Preventive Maintenance Tips

E regular inspection of the MSZ-GL12NA system is essential for optimal performance․ Ensure proper airflow by cleaning or replacing filters every 3 months․ Check the refrigerant level and inspect outdoor unit connections for leaks․ Monitor air filter condition and schedule professional maintenance annually․ Always follow safety guidelines when performing checks․ Adjust operation settings to suit seasonal needs for energy efficiency․ These steps help extend equipment lifespan and prevent issues․

Troubleshooting Mitsubishi MSZ-GL12NA

E common issues with the MSZ-GL12NA include error codes and malfunctions․ Always refer to the service manual for detailed diagnostics․ Address airflow problems, sensor malfunctions, or remote control issues promptly․ Regular maintenance prevents major breakdowns․ Ensure safety and efficiency by following the manual’s guidelines for troubleshooting․

Common Issues and Solutions

The manual addresses common problems such as the unit not starting, malfunctioning sensors, and airflow disruptions․ It offers solutions for troubleshooting remote control malfunctions, temperature control inaccuracies, and refrigerant leaks․ Additionally, it provides instructions for interpreting error codes and resolving issues related to outdoor unit performance․ Regular maintenance and cleaning of filters are recommended to prevent future issues․

Interpreting Error Codes

The Mitsubishi MSZ-GL12NA system displays error codes to diagnose issues․ For example, codes like E1 or E2 indicate specific problems such as power supply issues or sensor malfunctions․ Refer to the manual for a comprehensive list of error codes and their meanings․ The guide explains how to reset the system, troubleshoot airflow issues, or addresscontrol errors․ Always consult the manual for solutions before contacting professional service․

Technical Specifications

The Mitsubishi MSZ-GL12NA features cooling and heating capacities of 12,000 and 14,000 BTU/h, utilizing R-410A refrigerant․ It operates with a voltage range of 90-270 V, has an EER of 12․5, and features low noise levels, ensuring efficient performance․

Model-Specific Details

The Mitsubishi MSZ-GL12NA is designed for efficient cooling and heating, utilizing the R-410A refrigerant․ It operates on a voltage range of 90-270 V, making it suitable for various power sources․ With a cooling capacity of 12,000 BTU/h and heating capacity of 14,000 BTU/h, it ensures optimal temperature control․ The unit features a high EER rating and includes advanced airflow management for improved performance and energy efficiency․ It also supports connectivity for remote control and integrates seamlessly into modern heating and cooling systems․

Performance Metrics

The Mitsubishi MSZ-GL12NA delivers exceptional performance with its advanced cooling and heating capabilities․ It achieves an impressive EER of 15․0 and COP of 3․98, ensuring energy efficiency and optimal temperature control․ The unit’s airflow management system enhances performance, while its noise levels remain minimal for a operation․ These metrics ensure reliable and efficient operation in various conditions․

Electrical Requirements

The Mitsubishi MSZ-GL12NA operates on a standard voltage of 200-240V AC, requiring a 3-phase power supply․ Ensure proper grounding as specified in the manual for safety and performance․ Amperage requirements are listed in the unit’s specifications, and the system is designed for optimal operation at 50/60 Hz․ Always use the correct circuit breaker and wiring to prevent malfunctions․ The system is compatible with 3-phase power and requires proper phase sequence for efficient operation․ Follow the manual’s guidelines for installing and connecting electrical components to maintain energy efficiency and reliability․

Component Specifications

The Mitsubishi MSZ-GL12NA is equipped with advanced components to ensure reliable performance and efficiency․ It features a highly efficient compressor, optimized for quiet operation and energy savings․ The unit uses eco-friendly R410A refrigerant, meeting current environmental standards․ The evaporator and condenser are designed for optimal heat exchange, while internal wiring and connections are built for durability and safety․ These components work together to deliver consistent comfort and long-term reliability․